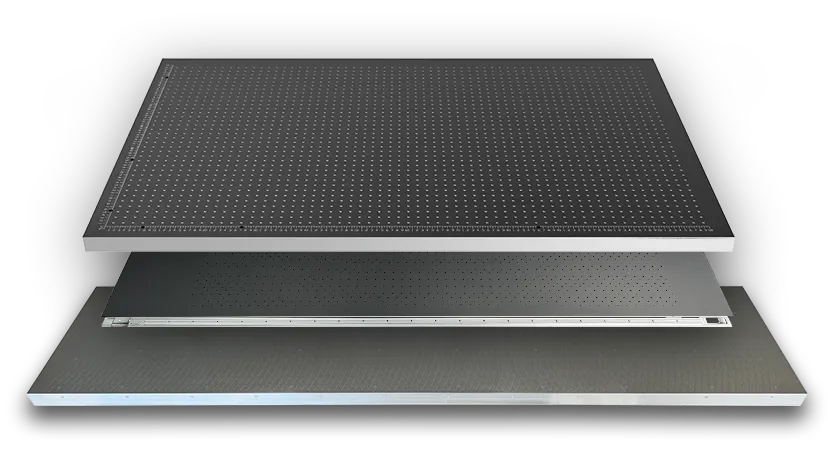

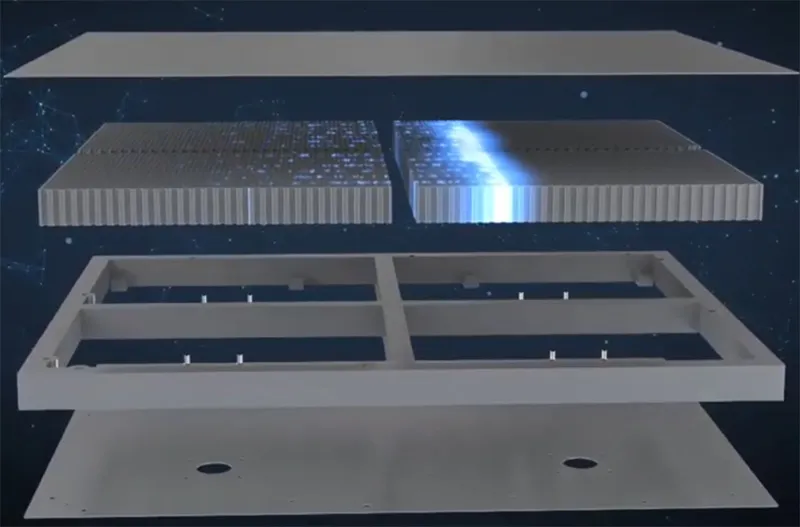

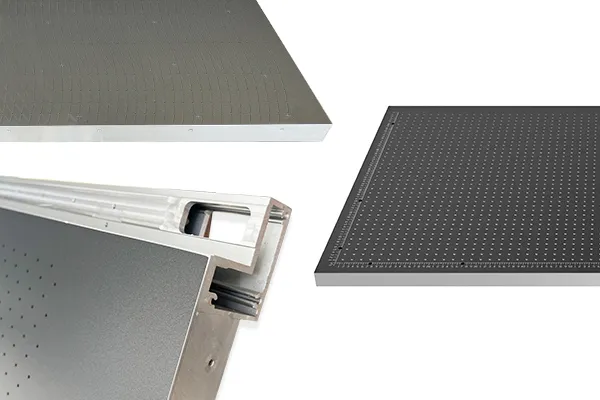

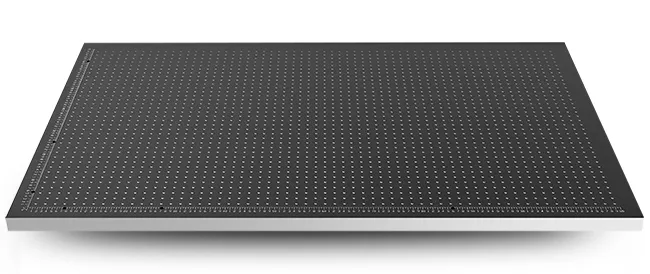

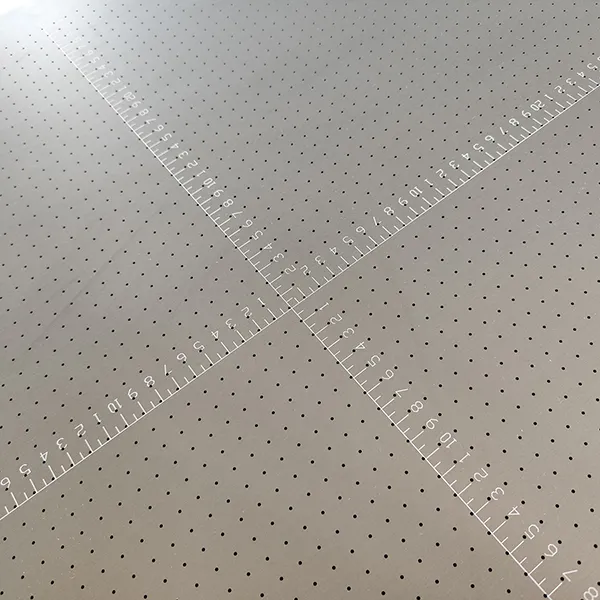

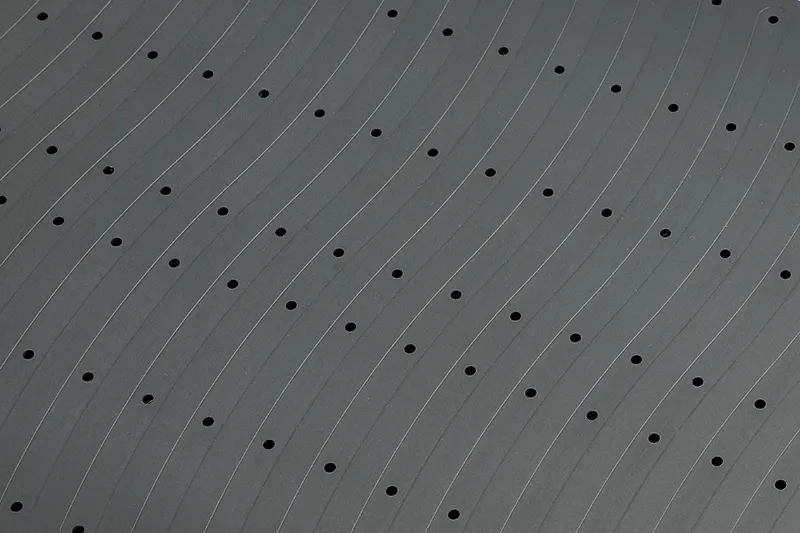

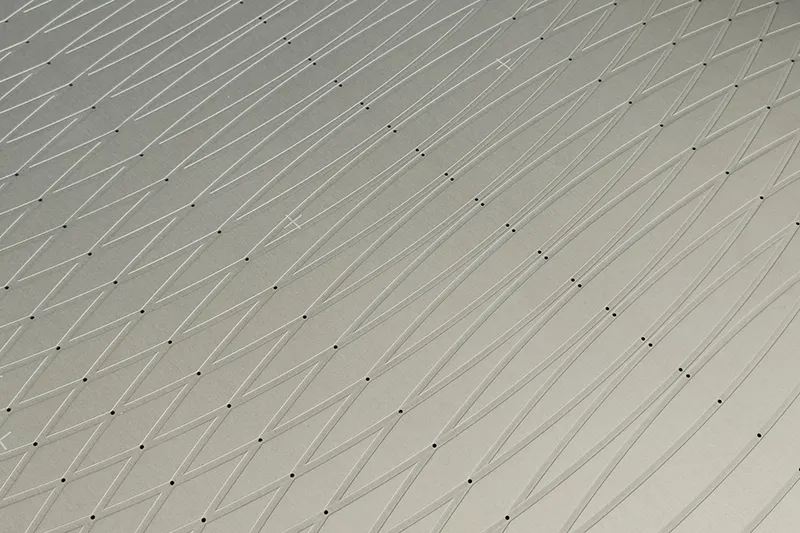

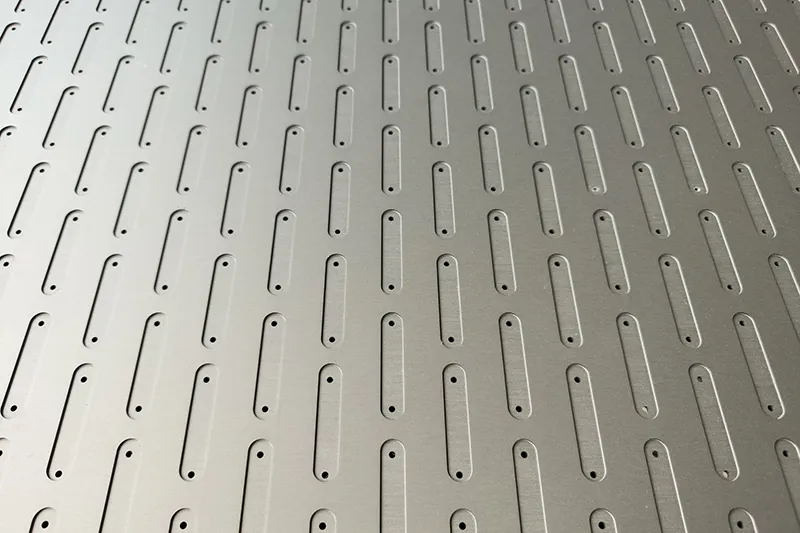

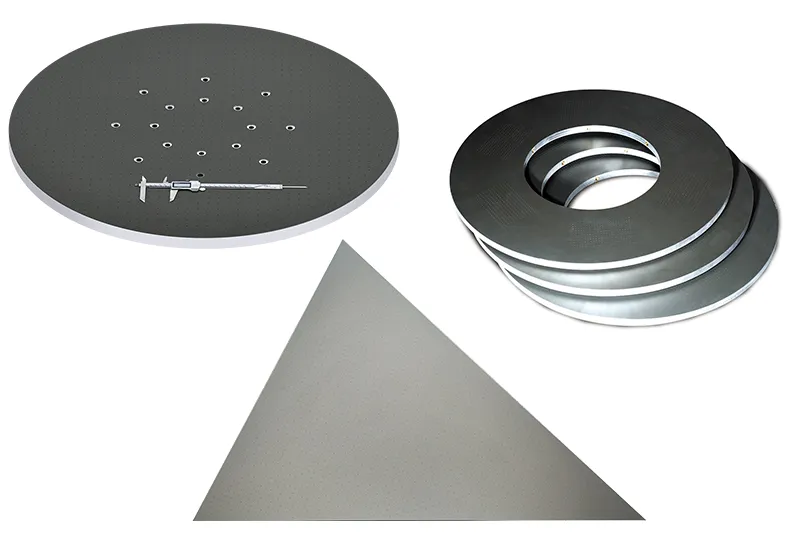

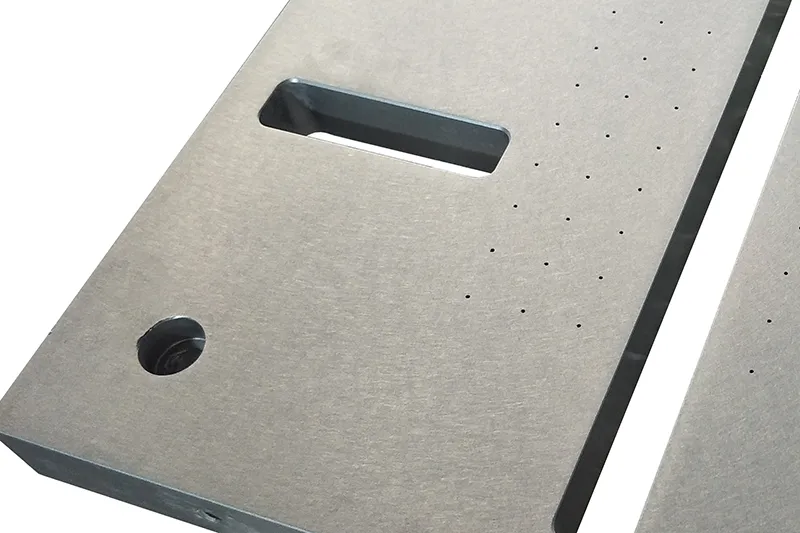

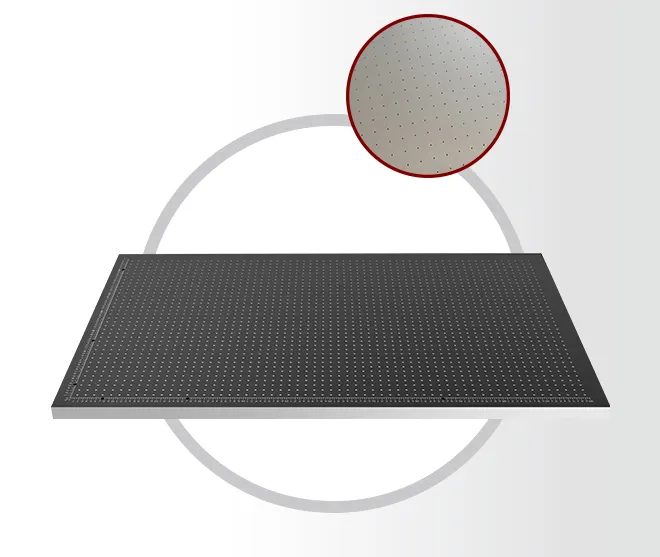

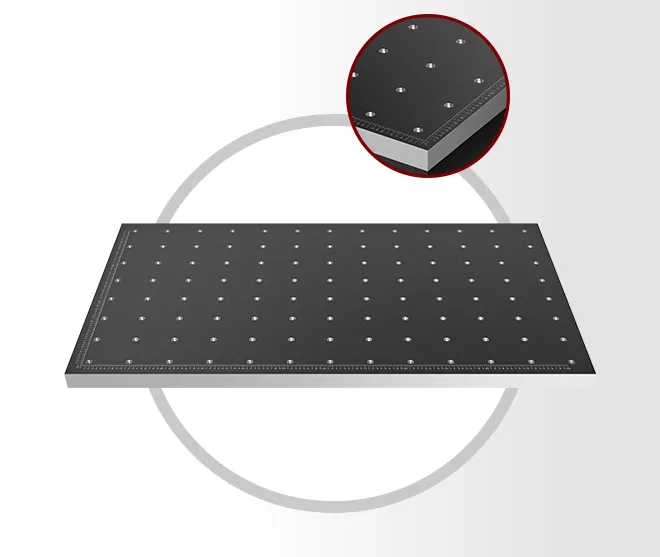

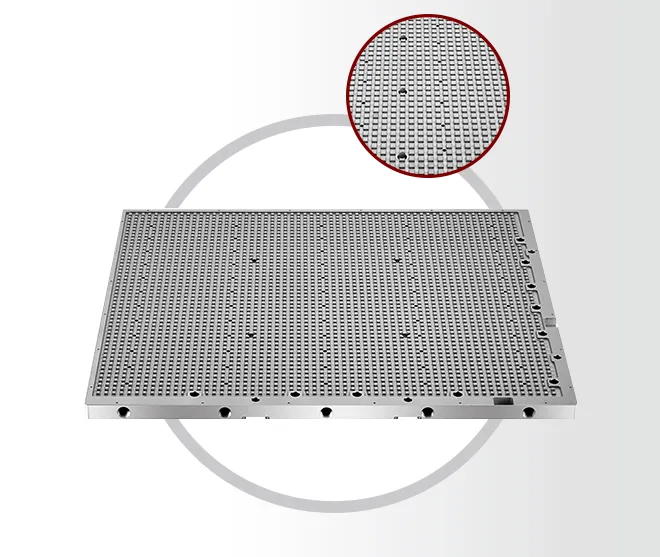

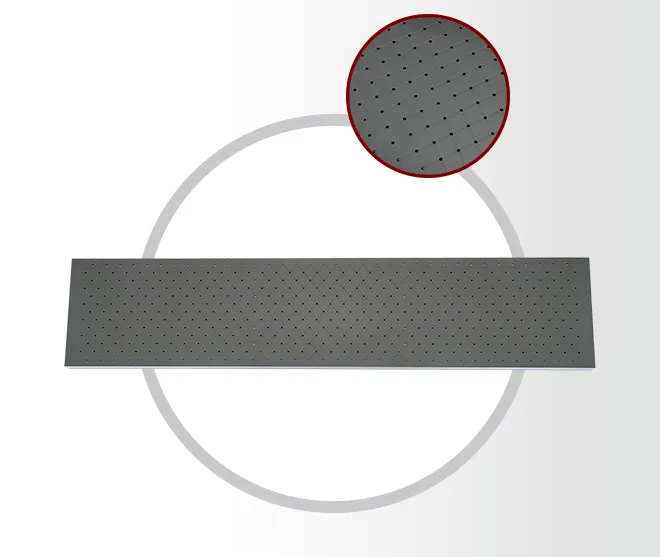

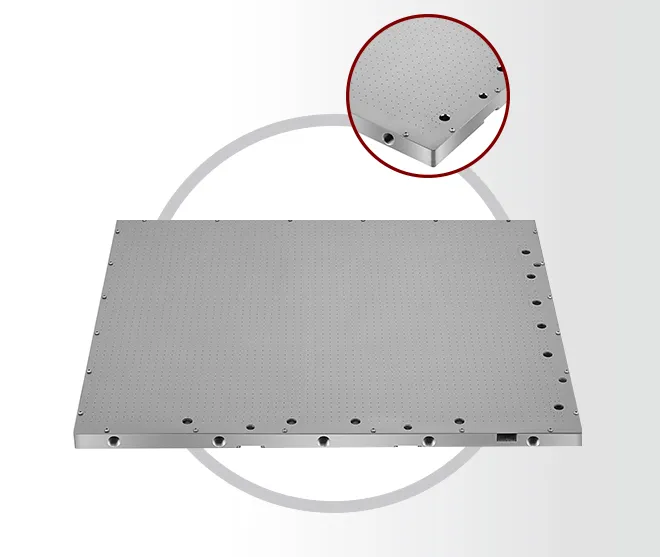

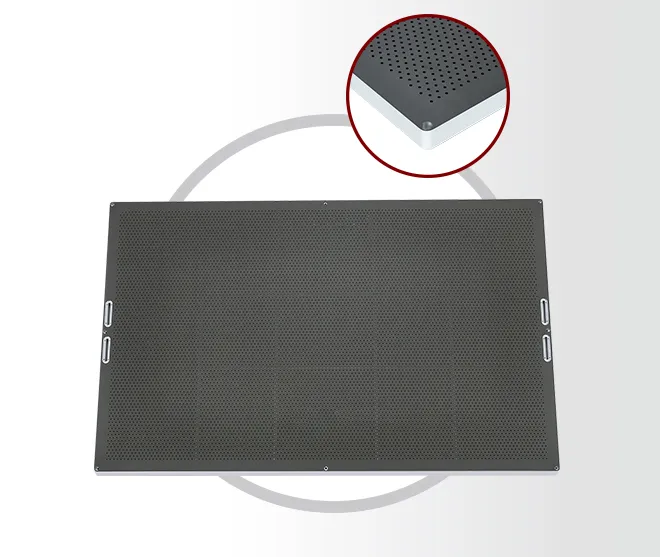

Custom Vacuum Tables

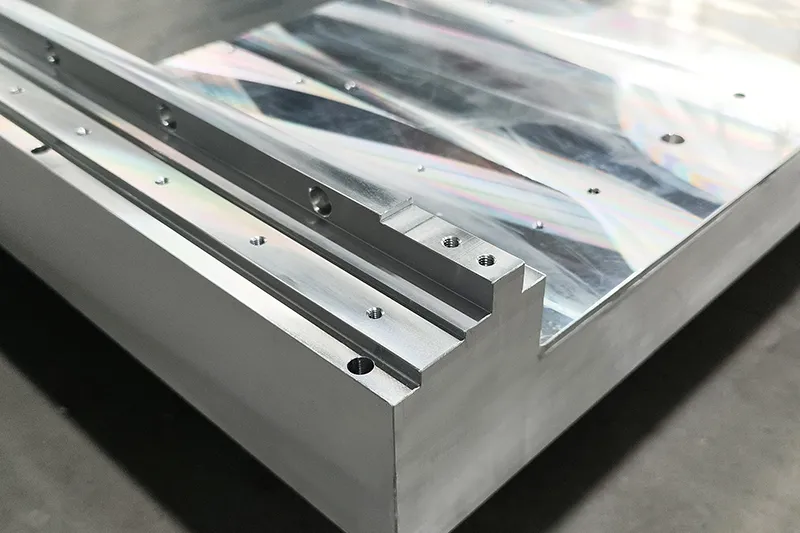

We Design and Make Vacuum Tables-

Over 13 years of experience

Over 13 years of experience in producing vacuum tables, with more than 600,000 units supplied globally.

-

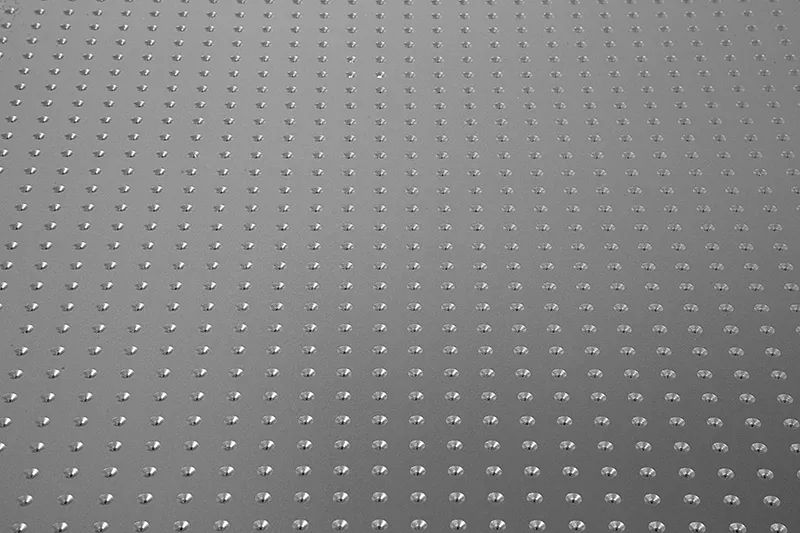

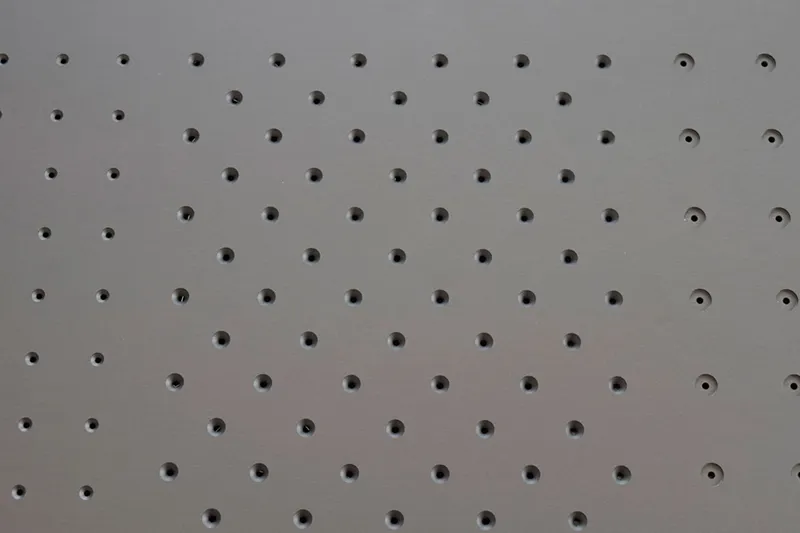

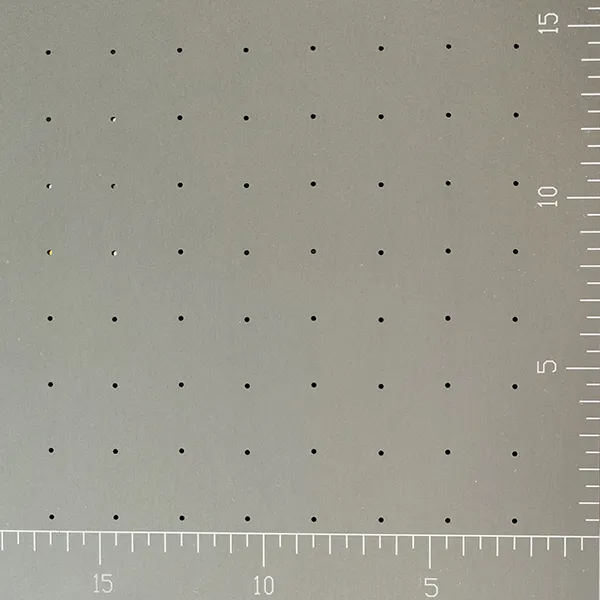

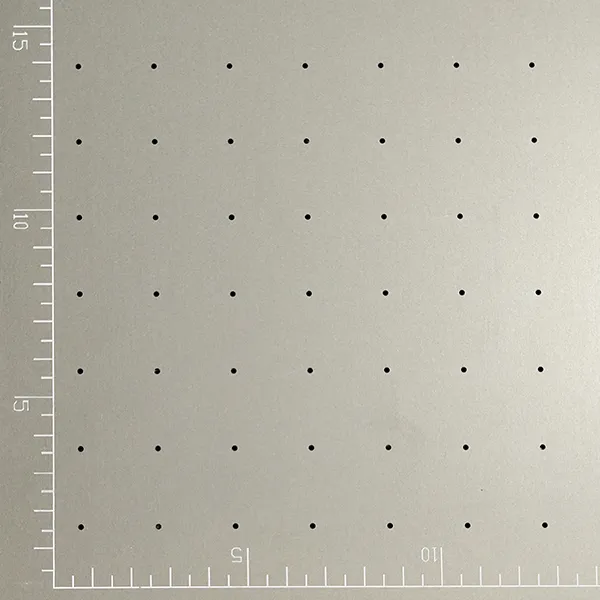

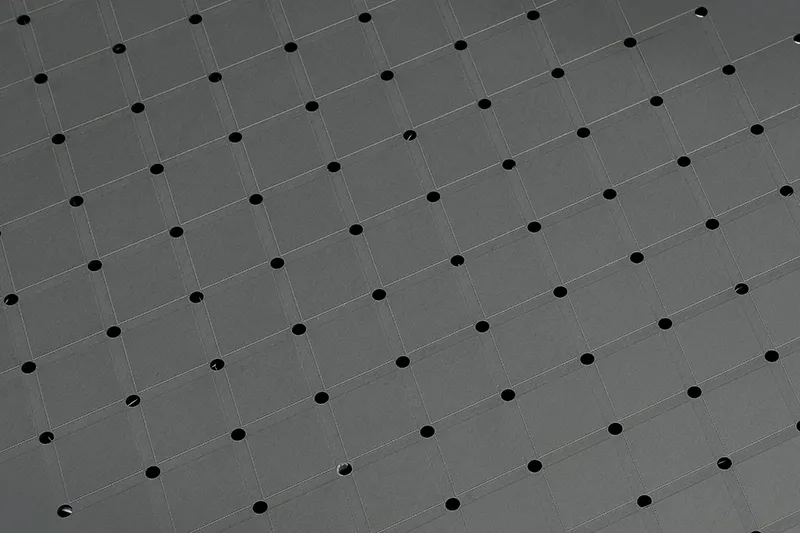

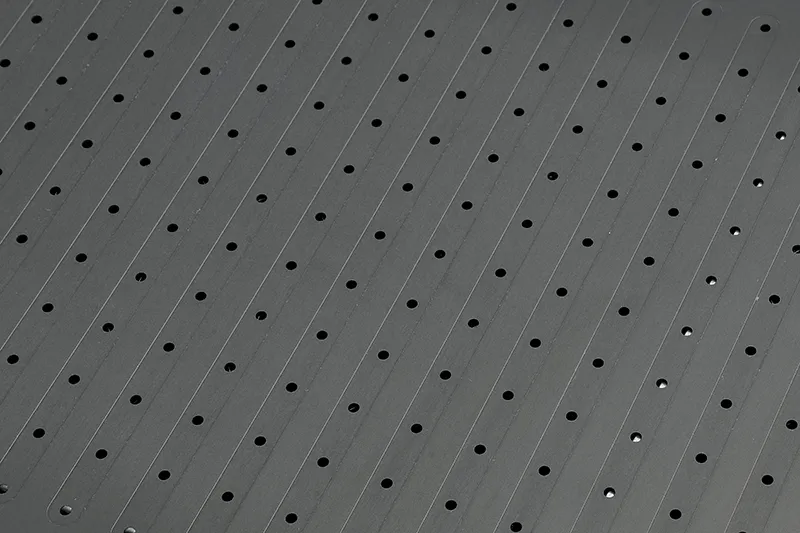

Industry leading flatness

Capable of producing vacuum tables with flatness up to 0.005mm, sizes ranging from 0.1m² to 8m², and platforms up to 4000mm x 2100mm without splicing.