Our Custom Manufacturing Capabilities

- 160 Over 160 employees

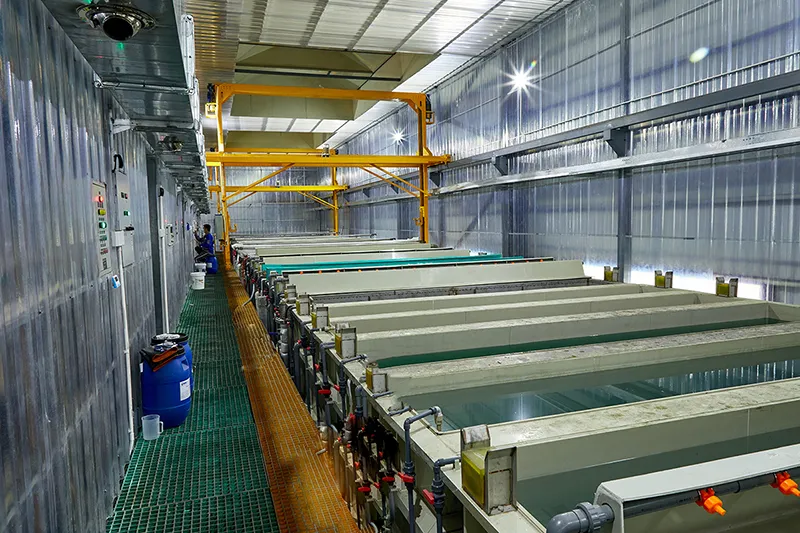

- 15,000+ A 15,000+ square meter facility

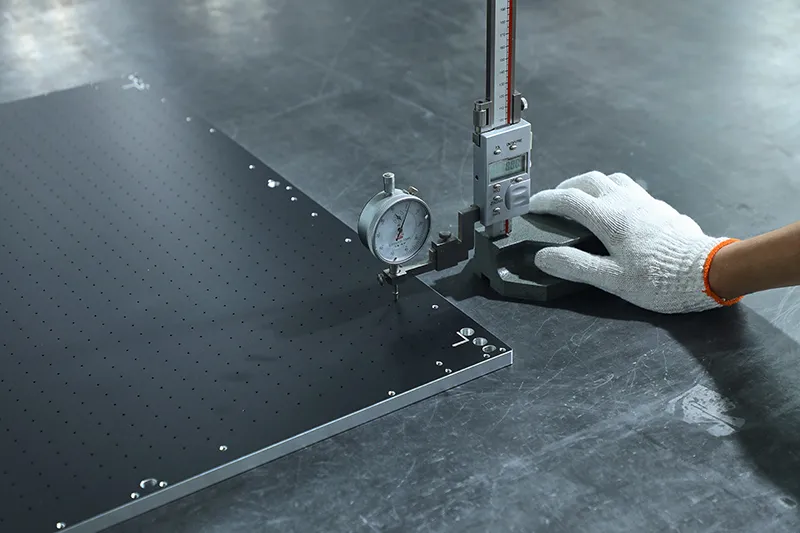

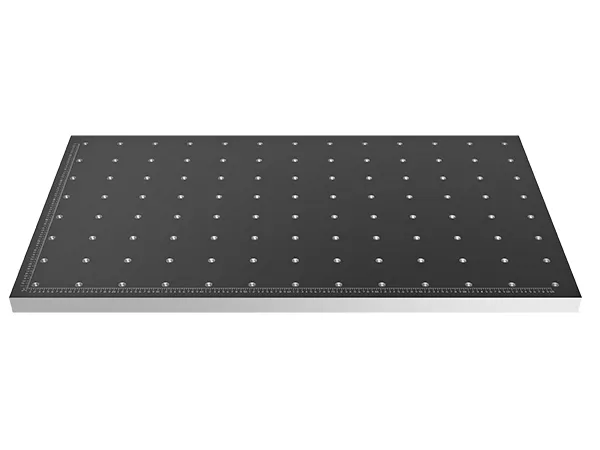

- 100 More than 100 specialized machines, including large CNC machines

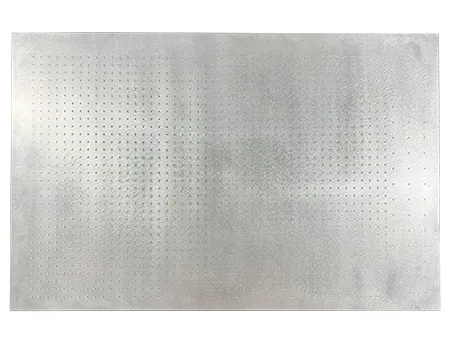

- 150,000Annual production capacity of 150,000 square meters