What types of customization services does Yimiwell offer?

We offer a full range of custom vacuum table services, including custom sizes, surface treatments, material selection, and suction functionality configurations.

How do I start the customization process?

You can contact our sales team to discuss your needs and budget. Our professional team will then work with you to confirm the requirements and design an initial plan.

What materials are available for custom vacuum tables?

We offer aluminum alloy and stainless steel material options.

Are there size limitations for custom vacuum tables?

Our customization services are highly flexible. We can produce vacuum tables as large as 4000mm x 2100mm (larger sizes can be spliced). The exact size will be determined based on your specific application.

What is the production time for custom vacuum tables?

The lead time varies based on the complexity of the vacuum table and the current order volume in our factory. The production is usually completed within 15 days after confirming the design and receiving the deposit. We maintain constant communication with you throughout the process, keeping you updated every step of the way to ensure everything progresses smoothly and on time.

Which vacuum table is suitable for my needs?

The choice mainly depends on your processing machine type and desired results. Our professional technical team can provide support and advice. While all our vacuum tables feature suction functionality, we also offer models with additional specialized features to meet diverse application needs. For temperature control, we offer heated vacuum tables and water circulation constant temperature vacuum tables.

How does a vacuum table work?

A vacuum table works by creating a vacuum environment to generate suction, which then holds objects in place. The process is as follows:

- Vacuum extraction: When the vacuum pump starts, it extracts air from the surface of the table, reducing the air pressure in that area. As the pressure decreases, air molecules become less dense, creating a pressure difference between the object and the table surface.

- Suction force: The pressure difference creates an inward suction force that is strong enough to secure the object on the table.

- Stability maintenance: After the object is secured, the vacuum pump continues to maintain the pressure, ensuring the suction force is strong enough to keep the object stable.

Can you manufacture a vacuum table according to a provided design drawing?

We can accommodate diverse customer needs, whether it’s customizing vacuum hole sizes or the overall size and shape of the table. From precision vacuum holes (0.3mm to 3.5mm) to large, complex table structures, we can fulfill these requirements with our advanced technology and efficient production process. For detailed inquiries, please contact our team and send us your design drawings.

What is the flatness achievable with the given dimensions?

Using advanced production equipment and a skilled technical team, we have successfully developed large vacuum tables (up to 8 square meters, 4000mm x 2100mm, without splicing) with a flatness of up to 0.05mm. For further details, please contact our team and send us your design drawings.

Can a vacuum table be designed to hold flat materials under the given conditions?

We excel in custom design capabilities and can create vacuum tables tailored to unique operating conditions and material characteristics. Our professional team will analyze the details of your specific conditions such as material properties, suction requirements, environmental temperature and humidity, and space constraints to ensure the design effectively holds materials flat while integrating seamlessly into your production process. For more information, please contact our team and send us your drawings.

What types of vacuum tables are available?

The core principle of vacuum tables remains consistent. They can be classified according to specific applications, such as printer vacuum tables, laser engraving machine vacuum tables, and can also be categorized based on additional functions, such as air-floating vacuum tables and heated vacuum tables.

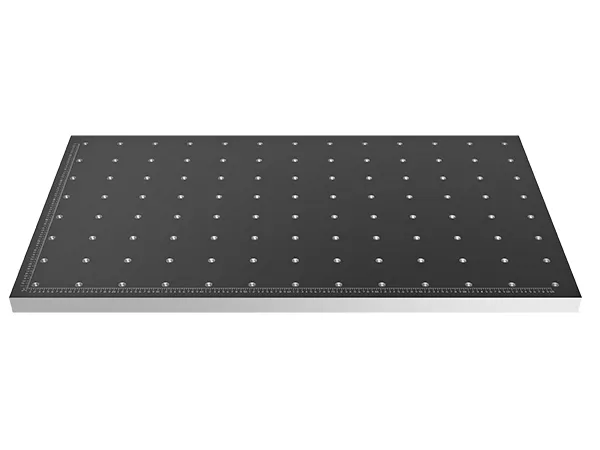

What should I consider when selecting a vacuum table?

The key factor to consider is the flatness of the vacuum table, as this directly impacts suction effectiveness. For larger platforms or heavier objects, it’s also important to consider deflection. The performance of the vacuum pump is equally important as it provides the suction power. Lastly, the material’s scratch resistance and strength should also be considered, as these factors influence the vacuum table’s durability. Our vacuum tables are made from aluminum alloy, offering excellent flatness, low density, high strength, and resistance to bending, deflection, and wear, making them an ideal choice.

What tasks are vacuum tables suitable for?

Vacuum tables securely hold both rigid and flexible materials, such as wood, metal, glass, plastic, and paper, ensuring they remain stable during processing. Common equipment using vacuum tables includes: flatbed printers, inkjet printers, digital printers, flexible cutting machines, screen printers, laser engraving machines, CNC machines, and more.

What should I be aware of when using a vacuum table?

After use, the table surface should be cleaned promptly to prevent corrosion and scratching. Regular maintenance is essential. Also, the vacuum pump’s performance should be monitored, and inspected or repaired if any signs of reduced power are detected.

We are a factory producing LCD displays, and during transport, the displays often get scratched. Which vacuum table should we choose?

We recommend an air floating vacuum table, which provides smooth suction and ample flotation. This vacuum table ensures that products are protected from friction during transport and handling, maintaining their quality.