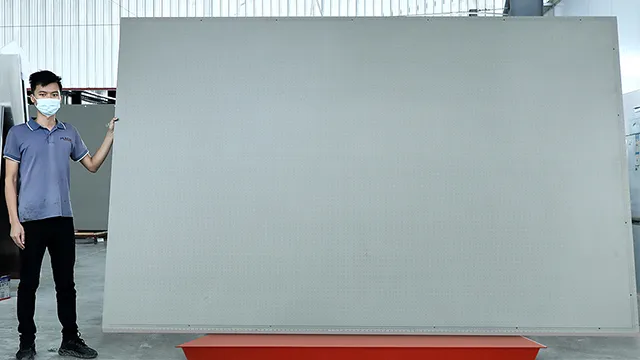

Vacuum Workholding Solution

Screen Printer Vacuum Table

Available in various sizes and configurations based on client requirements

Available in various sizes and configurations based on client requirements

With years of experience in manufacturing vacuum tables, we offer reliable solutions designed to hold materials firmly during the screen printing process. We provide a range of customization options, including platform size, vacuum hole configuration, suction area, hole diameter, number of suction holes, connection methods, and partitioned suction zones. Our vacuum tables are lightweight, highly rigid, and bonded with high accuracy, with flatness reaching an optimal 0.05mm.

Our screen printer vacuum tables feature an aluminum honeycomb core that ensures excellent flatness, with precision reaching up to 0.05mm. This guarantees stable material hold-down and accurate positioning during printing, leading to superior print quality.

The vacuum table is designed for uniform suction across all areas, ensuring secure material hold-down without displacement or deformation during the printing process. This consistency enhances stability and print quality.

Made entirely of aluminum alloy, our vacuum tables are lightweight yet offer high strength, rigidity, and resistance to bending. The density of the table is around 25-35kg per square meter, with a load capacity of up to 30kg without deformation. These properties make transportation, installation, and usage more convenient, while ensuring durability and stability.

The vacuum table surface can be treated with various processes, including PVDF coating, anodizing, and hard anodizing. The hard anodizing process provides surface hardness of HV500-700, making it highly resistant to scratches and wear, ensuring long-term durability and performance.

We offer fully customized vacuum tables, allowing clients to define surface size, vacuum hole diameter, spacing, suction area, suction hole diameter, and connection methods. This flexibility ensures that our vacuum tables meet the specific needs of each client, boosting product competitiveness and market share.

By securely holding substrates, our vacuum tables prevent shifting or distortion, ensuring consistent print accuracy. The excellent flatness of the tabletop further enhances this precision.

The quick material positioning enabled by the vacuum system eliminates the need for additional clamping, saving time and improving efficiency. Stable suction also reduces material movement during printing, which minimizes defects and enhances operational efficiency.

Our vacuum tables can be fully customized to meet specific customer requirements. Whether it’s the surface size and dimensions, vacuum hole diameter and spacing, suction area, suction hole diameter, number of suction holes, connection methods, or custom zones for independent suction or non-suction areas, we offer tailored solutions.

We are backed by a professional technical team that provides comprehensive support and consultation services. Whether customers face challenges during operation or need technical assistance, our team is ready to respond promptly with effective solutions.

For first-time users of vacuum tables, we offer training and guidance services, including operation training, maintenance and upkeep training, and troubleshooting. Through these training programs, customers gain a deeper understanding of the vacuum table’s performance, learn the correct operating methods, and acquire maintenance skills, ultimately improving both production efficiency and product quality.

Need assistance with vacuum tables? Contact our team for expert guidance!