Large-Scale Screen Separator Machine

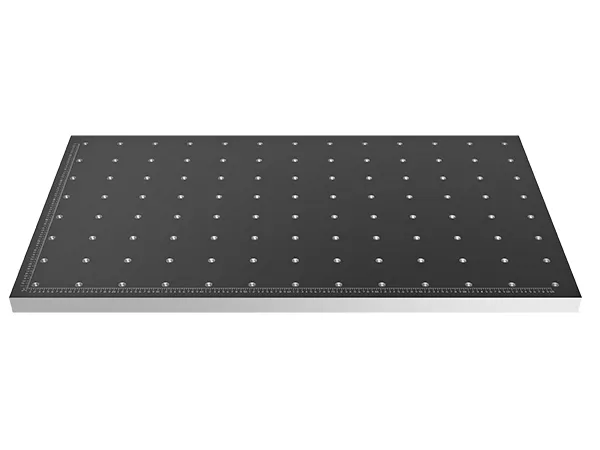

Designed for disassembling large-format screens such as TVs, touchscreens, computer monitors, and educational display panels, the large-scale screen separator machine provides efficient and precise separation for a wide range of devices.

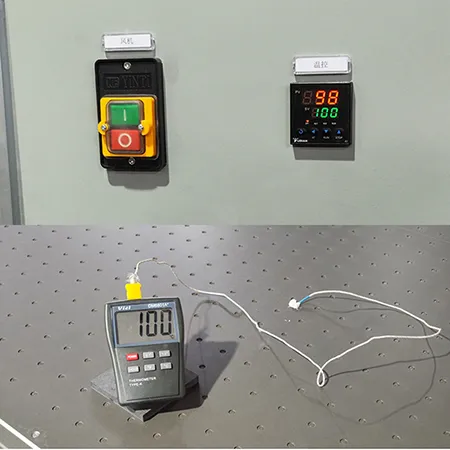

Advantages- Adjustable temperature control from 0–120°C

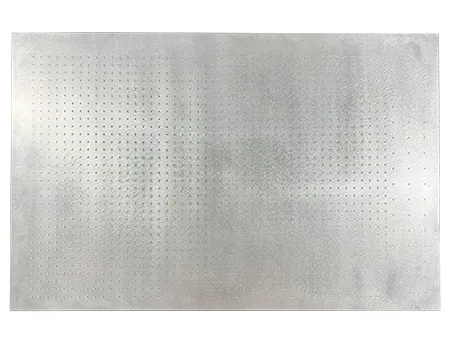

- Zoned vacuum control, supports multiple screen sizes from 55 to 120 inches

- Dimensions, hole diameter, and hole spacing can be tailored to specific requirements